Our vocation for research and our pilot plant

Ours spinning mill is characterised by highly innovative products and processes. Over the years we have extended our product range, venturing into new areas of technical textiles and fashion, and directed our research toward the goal of sustainable innovation.

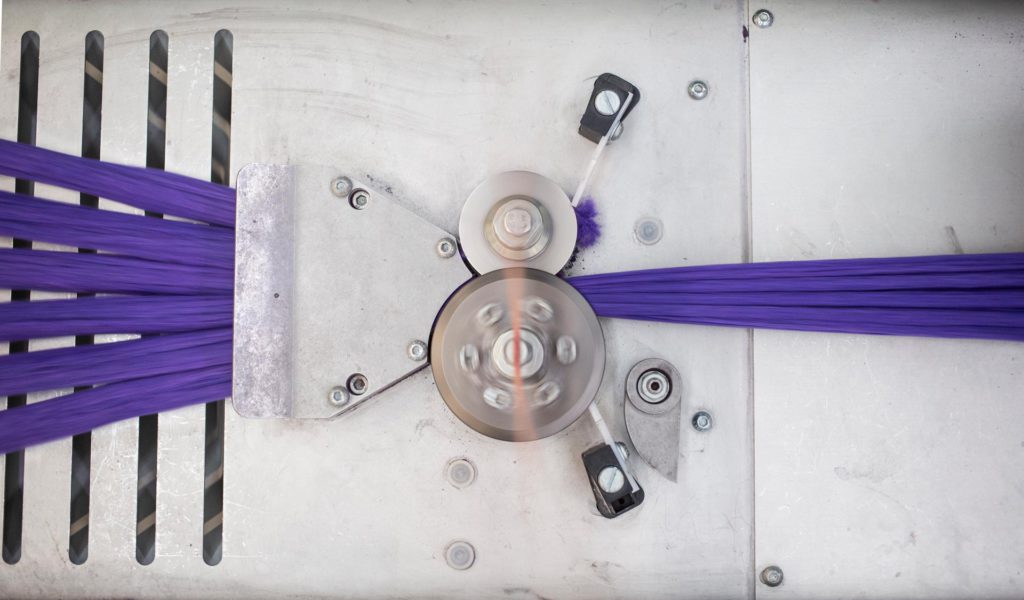

The fulcrum of our Research & Development is now a pilot plant covering 1200 square metres in our factory in Magnonevolo (Biella): a spinning plant on a reduced scale, covering the entire process of yarn production, from preparation of blends to the final cone, including a fully-equipped laboratory for testing fibres and yarns.

Our pilot plant allows us to work on different spinning technologies: open-end, ring, and combed and worsted wool spinning. It reproduces a real spinning plant on a reduced scale, with portions of industrial machinery permitting testing and development, producing realistic results that may be reproduced on an industrial scale, with the goal of eliminating any problems and discrepancies between prototyping and industrial production.

This facility is used to develop the in-house collections of our Marchi & Fildi, ECOTEC® and Filidea brands and to produce samples for customers and partnership projects.

Our pilot plant has its own raw materials warehouse, including the majority of natural, artificial and synthetic fibres, permitting rapid production of samples.

Several research projects related to “sustainability” are ongoing in our R&D plant. A very interesting case-study, also with a future perspective, is the project VALENTEX (Energy Valorisation of Textile Waste), which allowed to study and build a pilot reactor, capable of producing syngas and biochar, starting from textile waste and agricultural biomass waste. The reactor produced was built on a scale of capacity suitable for an application and demonstration use (pre-industrial prototype) with the aim of being able to analyze the technical-economic competitiveness of a solution strongly connected to the circular economy and the use of textile waste . The studies, very promising, are currently underway.

Development of the industry and focus on education

We believe in collaboration among key players at various stages in the production supply chain, and we are constantly working on projects in partnership with fibre manufacturers, universities and research centres.

Our current partnerships include one with ITS TAM in Biella, a technical secondary school of key importance for technical and professional education in the Biella textiles district.

Our premises in Magnonevolo are home to the clothing manufacture and knitting workshops attended by the school’s second-year students, who are also offered the opportunity of an apprenticeship in our plant, where they can test themselves against real production systems and the issues involved in their operation.

Magnolab, a network of textiles companies developing innovation

Marchi & Fildi and Filidea are among the founding partners of MagnoLab, a network of textiles companies of various kinds that work together in the industry.

Its mission is to work together in an organised way to develop innovation, research and projects relating to sustainability and the circular economy.

Through a physical network of pilot plants installed in a single location in Cerrione (Biella), MagnoLab permits collaborative development of innovative products and processes with rapid experimentation cycles on the basis of the lean management model.

It offers a unique setting for creation of prototypes for presentation to future customers, in which to find product and process solutions to be transferred directly to partner plants in order to proceed with mass production.

![Pop, sostenibile, irresistibile 💋

L’autunno/inverno 25-26 delle collezioni Marchi & Fildi e Filidea è tutto da scoprire. Tra le novità potrai esplorare articoli e titoli nuovi, cartelle colori rinnovate e l’ampliamento dell’offerta in stock service.

Lasciati ispirare dai nostri filati innovativi e, se non ci siamo incontrati durante l’ultima edizione di @pittimmagine Filati, scopri tutti i dettagli delle nuove collezioni nel nostro articolo di approfondimento

[LINK IN BIO]](https://www.marchifildi.com/wp-content/plugins/instagram-feed/img/placeholder.png)